Kinetic Engineering Unveils Advanced Robotic Chassis Line at Ahilya Nagar Facility

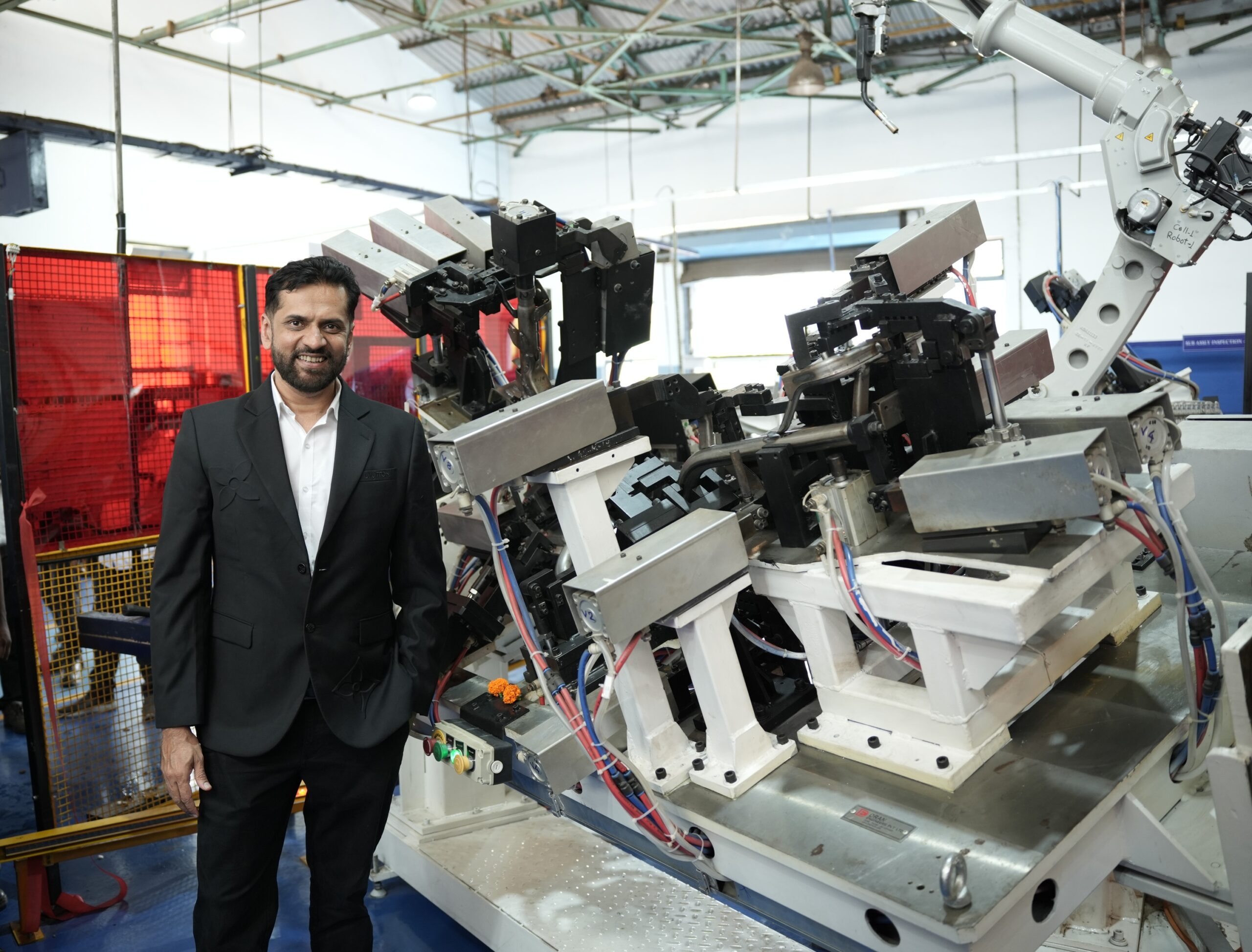

Ahilya Nagar, Maharashtra – September 3, 2025: In a significant leap towards automation and next-generation manufacturing, Kinetic Engineering Ltd., part of Kinetic India, has inaugurated its state-of-the-art Robotic Chassis Line at its facility in Ahilya Nagar. The new line integrates advanced robotic welding for the Kinetic DX EV, clamping auto fixtures, and a dedicated scooter framing cell—delivering unmatched precision, consistency, and higher productivity.

According to the company, the automation-driven setup reduces human error, enhances safety, and significantly improves operational efficiency, setting a new benchmark for Indian EV manufacturing.

Comprehensive Facility Upgrades

Alongside the Robotic Chassis Line, the Ahilya Nagar facility has received several critical upgrades designed to support modern production standards:

- Robotic Welding & Automation: Advanced robotic systems ensure precise, repeatable welds and superior structural integrity.

- Clamping Auto Fixtures & Scooter Framing Cell: Enhance accuracy and efficiency in chassis assembly.

- Upgraded Metal Body Panel Line: Hydraulic and mechanical presses, pneumatic clamping, and spot welding guns improve reliability and output quality.

- Modernized Paint Shop: A 7-tank process with CED coating followed by a metallic top coat ensures world-class corrosion resistance and premium finishes.

- Digitized Parts Store: Equipped with individual gauges, sub-assembly storage, and kit-based supply for optimized inventory management and smoother line operations.

A Vision for Future Manufacturing

Speaking on the occasion, Mr. Ajinkya Firodia, Vice Chairman & Managing Director, Kinetic Engineering Ltd., said:

“The future of manufacturing belongs to companies that can seamlessly integrate automation, precision, and sustainability into their processes. With the inauguration of our Robotic Chassis Line, we are not just upgrading a facility—we are reimagining how manufacturing should be done in India. This move positions us to deliver unmatched consistency and reliability while setting a benchmark for how automation can transform traditional industries.”

With these advancements, Kinetic Engineering is aligning itself with global standards in EV manufacturing, showcasing how Indian companies can combine automation, efficiency, and sustainability to strengthen the country’s position in advanced manufacturing.

Share this content:

Post Comment